Quality Inspection

No acceptance, no production, and no outflow of defective products

Quality / HSF Policy – Enhancing Quality Excellence

① Improving Incoming Quality at the Source (Incoming Material Management)

Strengthening at the source to ensure incoming materials meet quality standards through thorough inspection.

② Enhancing Product Manufacturing Quality (Production Management)

Strengthen quality management to improve product yield and overall quality.

③ Strengthened Product Inspection (Shipping Management) to Prevent Defective Products from Leaving the Facility.

Strengthen quality management to improve product yield and overall quality.

Raw material inspection equipment

Shaking sieve machine

Ensure that the magnesium particle size meets the specifications to optimize the molding process.

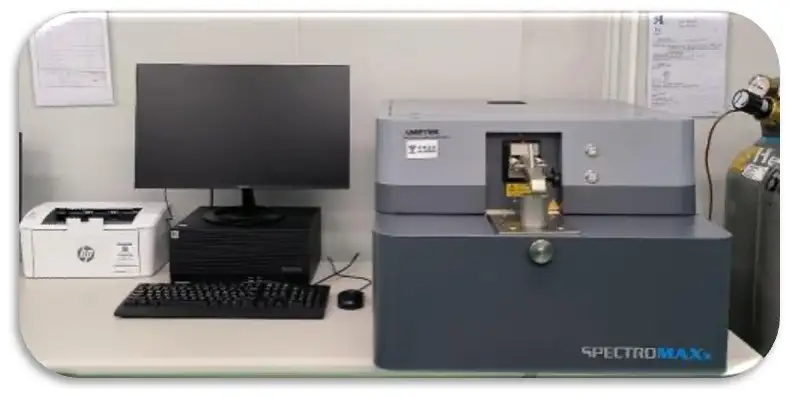

Spectrometer

The spark direct reading spectrometer uses high-energy sparks to generate plasma from metal surfaces. By analyzing the emitted spectrum, it determines the composition of metals and alloys, ensuring raw materials meet international standards.

XRF

X-ray Fluorescence Spectrometer (XRF spectrometer for short) is a non-destructive material quality measurement method for rapid quantitative detection of elemental composition of solid and liquid samples.