Research Development

Research Development

Leveraging the group’s extensive core mold technologies and years of mold development experience, 宏葉 can collaborate with customers in simultaneous product development, providing cost-effective and efficient mold design and component solutions. With a diverse range of approaches, 宏葉 is equipped to meet customers’ design and mass production requirements.

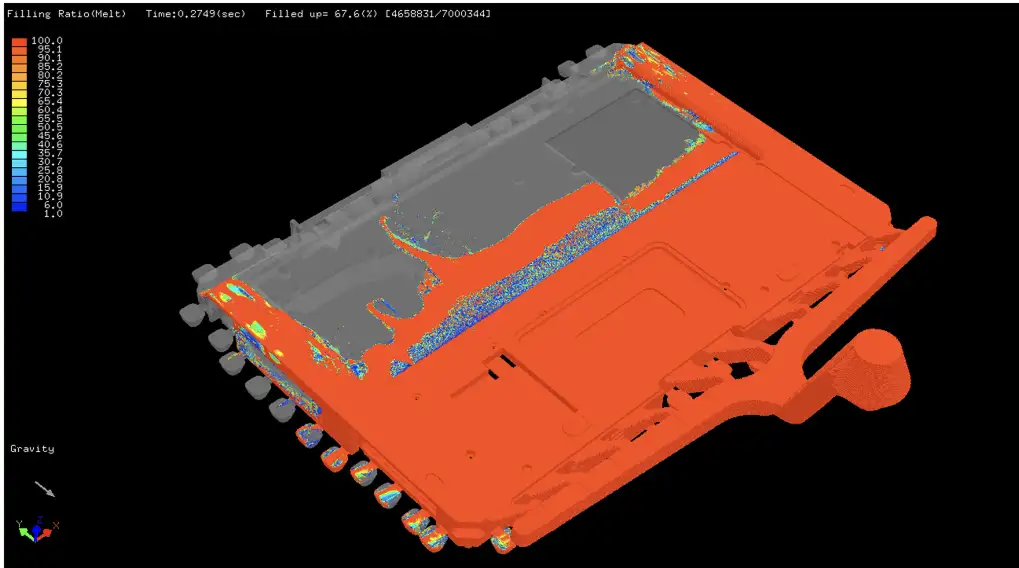

Mold Design and Mold Flow Analysis

Mold flow analysis helps determine the optimal placement of gates and cooling channels, as well as the extent and distribution of shrinkage, before the actual mold machining begins. Analysis Items:Injection molding simulation analysis、Process parameter optimization analysis、Weight reduction design molding analysis、Appearance defect improvement analysis for injection parts、Product structure improvement analysis

模具開立

Equipped with a wide range of machining equipment required for mold development, including CNC milling machines, laser welders, 2.5D measurement systems, TIG welding machines, as well as various lathes, grinders, and drilling machines. The entire process, from 3D drawing, mold base estimation, machining cost estimation, on-site assembly, mold testing, customer design changes, to mold modifications, is all handled in-house.