Quality Inspection

No acceptance, no production, and no outflow of defective products

Quality / HSF Policy – Enhancing Quality Excellence

① Improving Incoming Quality at the Source (Incoming Material Management)

Strengthening at the source to ensure incoming materials meet quality standards through thorough inspection.

② Enhancing Product Manufacturing Quality (Production Management)

Strengthen quality management to improve product yield and overall quality.

③ Strengthened Product Inspection (Shipping Management) to Prevent Defective Products from Leaving the Facility.

Strengthen quality management to improve product yield and overall quality.

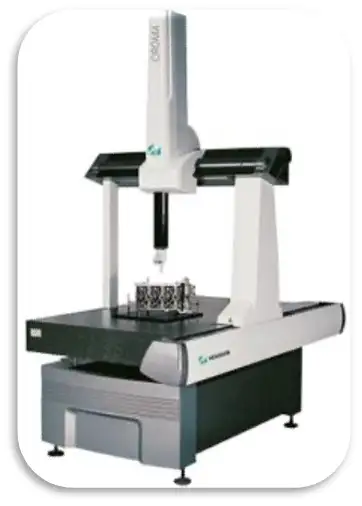

Measurement control equipment

Three-dimensional CMM

Contact measuring instruments, creating high-precision/high-quality/high-durability measuring instruments.

2.5D Projector OMM

Non-contact measuring instrument.

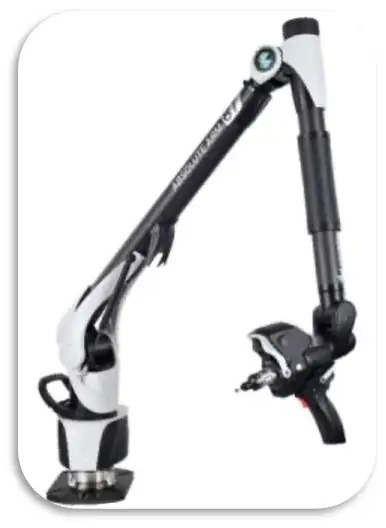

3D scan

Advanced intelligent self-monitoring analysis and reporting technology system provides all-round diagnostic monitoring for the reliability of various measurements.

X-ray Penetration Imaging System CT

The microme|x DXR-HD is a 180kV high-resolution microfocus X-ray system for real-time, automated inspection of solder joints and components. With optional tomography and x|act software, it enables precise μAXI inspection based on CAD.